Lásertech alvic

29 September 2015

The laser edging provides the perfect aesthetic for the manufacturing of design furniture with more durability and manufacture warranty.

Investment in technology and innovation have always been a hallmark of Alvic, a company that positions itself as a leader in the manufacturing and distribution of components for home furnishings. The excellent properties, quality, versatility and decorative value of Alvic products have made the company a benchmark in the European industry, not only furniture but also in designs, finishes and new materials for coatings and back boards manufacture of parts and finished products.

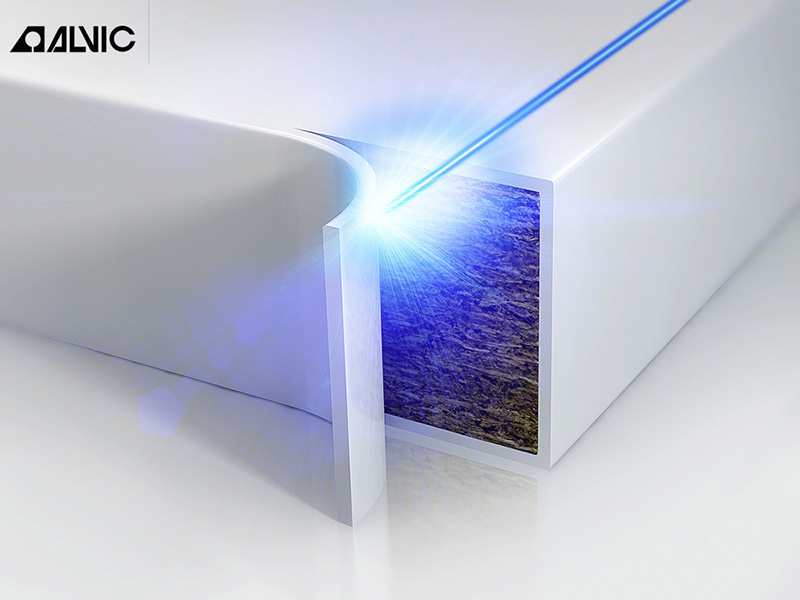

Its latest and revolutionary advance in the production process is the use of laser technology in the edging of pieces over the use of conventional adhesives. This edging system allows the connection between the rim and the backboard using a CO2 laser beam, achieving perfect aesthetics for the manufacture of parts for furniture in general.

The LaserTtech technology allows the connection between the rim and the backboard using a CO2 laser beam

- ALVIC LASER TECHNOLOGY

- Higher sealing and durability quality.

- Perfect sealing and finish.

- Prevents dirt between boards.

- Prevents yellowing of the joints.

- Increased resistance to light and high temperatures.

- Water resistance and moisture.

- GLUE OR OTHER ADHESIVES

- Colour change.

- Dirt may penetrate the joints.

- Swelling by moisture or water contact.

- Resistance decrease due to high temperatures.

- Absence of decorative value.